[ad_1]

The manufacturing trade has lengthy been a beacon of innovation, repeatedly evolving to satisfy the calls for of contemporary manufacturing. Nevertheless, the arrival of synthetic intelligence (AI) is propelling this sector into unprecedented realms of effectivity and functionality, with quite a few AI use circumstances in manufacturing revolutionizing processes and outcomes.

As an knowledgeable within the manufacturing trade, I’ve seen firsthand how AI options are reworking the sector. From predictive upkeep to high quality management, AI purposes are revolutionizing manufacturing processes and bettering operational effectivity throughout the board.

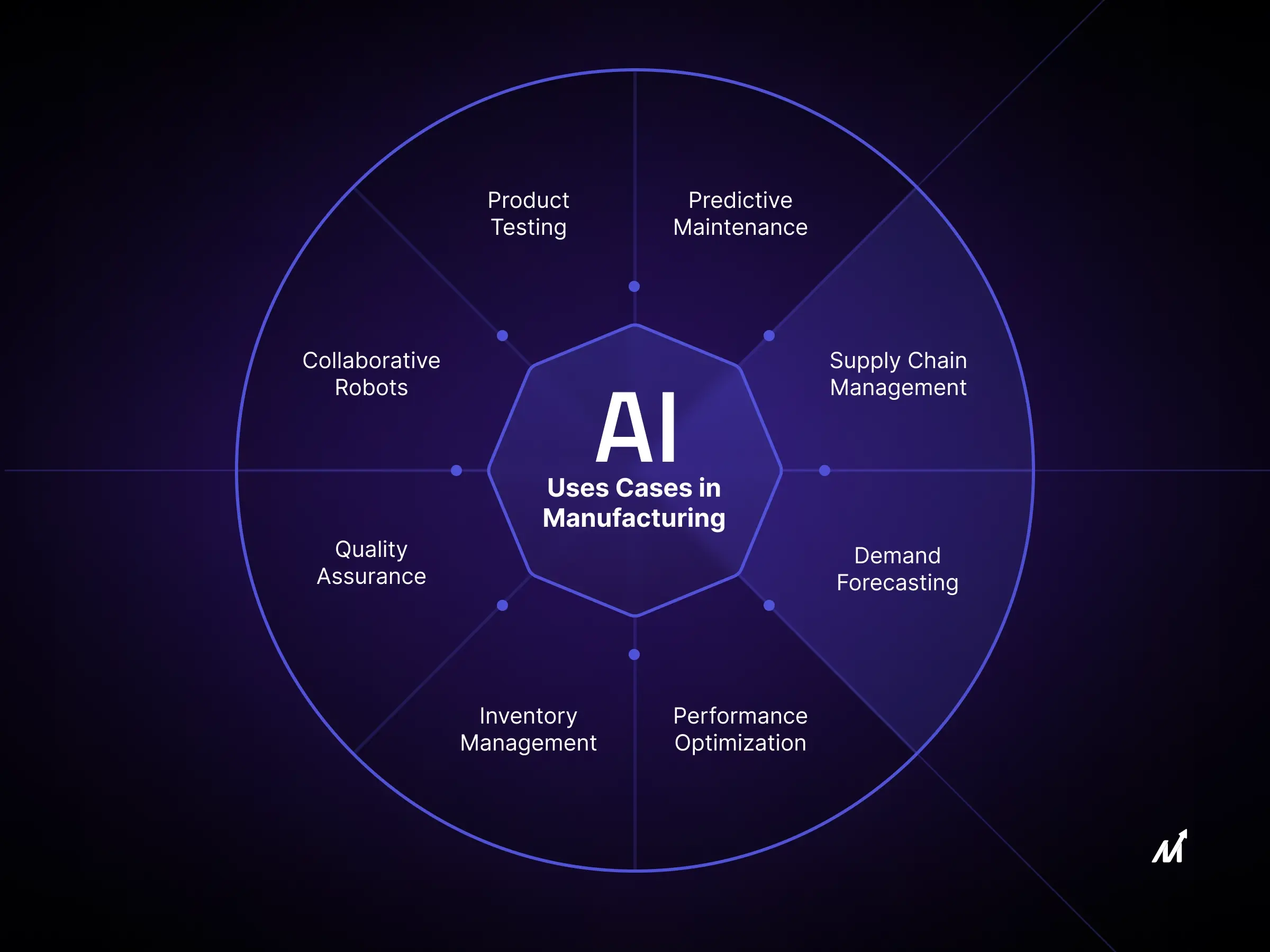

AI Use Instances within the Manufacturing Trade

One of the thrilling AI use circumstances in manufacturing is predictive upkeep. By leveraging machine studying algorithms and sensor knowledge, producers can now predict when gear is more likely to fail, permitting them to schedule upkeep proactively and keep away from pricey downtime. AI-powered predictive upkeep can scale back unplanned downtime by as much as 50% and enhance gear availability by 10-20%.

Generative AI is one other thrilling space of AI that’s reworking the manufacturing trade. This know-how makes use of machine studying algorithms to generate new designs and optimize present ones, enabling producers to create extra progressive and environment friendly merchandise.

AI is revolutionizing manufacturing processes from the store ground to your entire provide chain, making a transformative affect on manufacturing methodologies. The numbers communicate for themselves: by 2027, the AI market throughout the manufacturing trade is projected to succeed in a powerful $10.07 billion. However what does that appear to be in follow? On this put up, we’ll discover game-changing AI use circumstances reshaping manufacturing as we all know it. Get able to see how AI is making manufacturing smarter, sooner, and extra environment friendly than ever earlier than.

1. Manufacturing Course of Optimization

Generative AI can optimize manufacturing manufacturing processes. By analyzing historic course of knowledge and simulating completely different eventualities, generative AI can determine optimum course of settings that enhance effectivity, scale back waste, and improve product high quality. It may well assist producers streamline operations and scale back prices whereas bettering general efficiency.

A number one automotive producer used generative AI to revolutionize automotive design. By inputting parameters corresponding to materials power, weight, and security necessities, the AI algorithm generated a number of design alternate options that have been lighter and stronger than conventional designs. This led to the manufacturing of extra fuel-efficient autos with enhanced security options, setting new requirements in automotive design innovation.

2. Additive Manufacturing

Additive manufacturing, also referred to as 3D printing, is one other space the place generative AI is making a major affect. By robotically producing optimum half designs and print parameters primarily based on desired efficiency traits and materials properties, generative AI can scale back the time and price of additive manufacturing whereas bettering half high quality and efficiency. This use case of AI is a game-changer for producers trying to leverage the advantages of additive manufacturing of their operations.

An aerospace producer utilized generative AI to reinforce their additive manufacturing course of for plane parts. The AI-generated designs minimized materials utilization whereas sustaining structural integrity, resulting in a 20% discount in materials prices and a 30% lower in manufacturing time. The efficiency of the aerospace components improved by 25%, contributing to greater gas effectivity and sturdiness of the plane.

AI-powered robotics and automation are reworking the manufacturing trade. They permit producers to enhance effectivity, scale back prices, and improve product high quality. From collaborative robots to machine imaginative and prescient programs, these applied sciences are revolutionizing the way in which producers function.

3. Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work safely alongside human staff on meeting traces and in different manufacturing environments. Through the use of AI and machine imaginative and prescient, cobots can adapt to altering duties and environments, decreasing the necessity for handbook programming and rising flexibility in manufacturing operations. It may be a hit for producers trying to enhance effectivity and scale back time whereas making certain the security of their human staff.

A serious electronics producer deployed cobots on their meeting line, rising manufacturing effectivity by 30%. The cobots, utilizing AI and machine imaginative and prescient, tailored to completely different product fashions with out in depth reprogramming, leading to a 25% discount in setup time for brand spanking new product traces. Employee security incidents decreased by 40%, whereas general manufacturing time was lowered by 20%.

4. Machine Imaginative and prescient for High quality Inspection

Machine imaginative and prescient is one other highly effective AI know-how reworking high quality inspection in manufacturing. Through the use of deep studying algorithms and high-resolution cameras, machine imaginative and prescient programs can robotically detect defects and anomalies in merchandise and parts, bettering inspection accuracy and pace. This AI use case may also help producers determine high quality points which are tough or unimaginable for human staff to detect, decreasing the chance of product remembers and bettering general high quality.

A pharmaceutical producer firm applied machine imaginative and prescient programs geared up with deep studying algorithms to examine their packaging line. The AI-powered system robotically detected defects in labels, seals, and packaging integrity at a pace and accuracy unattainable by human inspectors. This lowered the chance of faulty merchandise reaching shoppers and minimized pricey remembers, making certain high-quality requirements.

5. Automated Materials Dealing with

AI-powered automated materials dealing with programs are additionally reworking the manufacturing trade. Through the use of machine studying algorithms and robotics, these programs can optimize the routing and scheduling of uncooked supplies, scale back the chance of errors and accidents, and enhance general throughput and productiveness. AI helps producers trying to streamline their operations and scale back prices whereas bettering effectivity and security.

Within the meals and beverage trade, an AI-powered automated materials dealing with system optimized the transportation and storage of uncooked supplies. The system’s optimization algorithms improved routing effectivity by 25% and lowered errors by 15%. This enhancement elevated general throughput by 20% and lowered downtime by 18%, making certain well timed supply of uncooked supplies to manufacturing traces.

AI can also be reworking provide chain and logistics optimization within the manufacturing trade. From demand forecasting and planning to stock optimization and provider threat evaluation, AI is enabling producers to make extra knowledgeable choices and enhance their general efficiency.

6. Demand Forecasting and Planning

Demand forecasting and planning are important areas wherein AI is considerably impacting manufacturing. By analyzing historic gross sales knowledge, market developments, and exterior components corresponding to climate and financial indicators, AI-powered demand forecasting instruments can generate extra correct predictions, enabling producers to higher plan manufacturing and stock ranges. This utility may also help producers scale back prices, enhance effectivity, and improve buyer satisfaction.

An attire producer used AI-powered demand forecasting instruments to research historic gross sales knowledge and market developments. The AI offered demand predictions with 95% accuracy, enabling simpler manufacturing and stock planning. This lowered extra inventory by 20% and stockouts by 25%, resulting in a 15% enchancment in buyer satisfaction and a ten% enhance in gross sales.

7. Stock Optimization

Stock optimization is one other space the place AI is reworking the manufacturing trade. By analyzing historic knowledge and real-time demand alerts, AI-based stock optimization instruments can predict optimum stock ranges and automate replenishment processes, decreasing the chance of stockouts and overstocking. Producers can scale back stock prices and enhance stock turns, resulting in vital value financial savings and improved operational effectivity.

A shopper electronics firm applied AI-based stock optimization instruments, leading to a 20% discount in stock holding prices. The AI predicted optimum stock ranges with 98% accuracy and automatic replenishment processes, decreasing stockouts by 30% and overstocking by 25%. This led to a 15% enhance in stock turnover and vital value financial savings.

8. Provider Danger Evaluation

Lastly, AI can also be reworking provider threat evaluation within the manufacturing trade. AI-powered provider threat evaluation instruments can determine potential dangers corresponding to financial instability, geopolitical occasions, and pure disasters by analyzing knowledge from a number of sources, together with monetary stories, information articles, and social media. AI may also help producers proactively tackle points earlier than they affect operations, decreasing the chance of provide chain disruptions and bettering general efficiency.

An automotive producer adopted AI-powered provider threat evaluation instruments to observe and consider provider dangers. The AI recognized potential dangers with 90% accuracy, corresponding to provider monetary instability and geopolitical occasions. This proactive method allowed the producer to mitigate dangers earlier than they impacted operations, decreasing provide chain disruptions by 25% and making certain a extra dependable provide chain.

Key Takeaway:

AI is revolutionizing manufacturing with predictive upkeep, high quality management, provide chain optimization, stock administration, demand forecasting, generative design, manufacturing course of optimization, additive manufacturing enhancements, AI-powered robotics, and automation, together with cobots and machine imaginative and prescient for inspection. These improvements streamline operations whereas boosting effectivity and product high quality.

Predictive analytics is a game-changer on the earth of producing. By leveraging the ability of machine studying algorithms and historic knowledge, producers can now anticipate potential points earlier than they happen. This proactive method not solely saves money and time but additionally ensures a smoother, extra environment friendly manufacturing course of.

9. Tools Failure Prediction

Tools failure prediction is among the most vital purposes of predictive analytics in manufacturing. By analyzing sensor knowledge and machine efficiency metrics, AI algorithms can determine patterns and anomalies that point out a possible breakdown. This AI utility permits upkeep groups to schedule repairs or replacements earlier than the gear fails, minimizing downtime and maximizing productiveness.

For instance, a number one automotive producer applied an AI-powered predictive upkeep system and noticed a 20% discount in unplanned downtime. By predicting and stopping gear failures, they optimized their manufacturing course of and improved general operational effectivity.

10. Manufacturing High quality Optimization

Producers can use predictive analytics to optimize manufacturing high quality. By analyzing knowledge from numerous phases of the manufacturing course of, AI algorithms can determine components that contribute to high quality points. AI permits producers to make data-driven choices and implement corrective actions to enhance product high quality.

An actual-world instance of it is a world electronics producer that used predictive analytics to cut back defect charges by 50%. By figuring out the basis causes of high quality points and making focused enhancements, they have been capable of considerably improve their manufacturing processes and ship higher-quality merchandise to their clients.

11. Course of Parameter Optimization

Predictive analytics also can assist producers optimize course of parameters. By analyzing historic course of knowledge and figuring out the optimum settings for every stage of manufacturing, AI algorithms may also help producers fine-tune their processes for max effectivity and high quality.

A number one chemical producer used predictive analytics to optimize their batch manufacturing course of, leading to a 15% enhance in yield and a 20% discount in power consumption. By leveraging the ability of information and AI, they have been capable of streamline their operations and obtain vital value financial savings.

Digital twins and simulation are:

Highly effective instruments within the manufacturing trade.

Permitting firms to create digital replicas of their merchandise and processes.

Even total factories.

When mixed with AI, these applied sciences supply unprecedented alternatives for optimization and innovation.

12. Digital Product Testing and Validation

One of the thrilling purposes of AI in digital twins is digital product testing and validation. By making a digital duplicate of a product and subjecting it to numerous simulated situations, producers can determine potential points and optimize designs earlier than making a bodily prototype. This method saves money and time and permits for extra iterative and progressive product growth.

For instance, a number one aerospace producer used AI-powered digital twins to simulate and optimize the design of a brand new plane engine. By working 1000’s of digital exams and analyzing the outcomes with AI, they recognized the optimum design parameters and lowered growth time by 50%.

13. Manufacturing Line Simulation

Enterprises can use AI-powered digital twins to simulate and optimize manufacturing traces. By making a digital duplicate of a manufacturing unit ground and utilizing AI to research numerous eventualities, producers can determine bottlenecks, optimize layouts, and check new configurations with out disrupting precise manufacturing.

A worldwide automotive producer used AI-driven manufacturing line simulation to optimize their meeting course of, leading to a 30% enhance in throughput and a 20% discount in cycle time. By leveraging the ability of digital twins and AI, they have been capable of make data-driven choices and repeatedly enhance their manufacturing operations.

High quality management and inspection are important features of the manufacturing course of, making certain that merchandise meet the required requirements and specs. Because of this, AI is revolutionizing this space, providing new methods to automate and optimize high quality management processes.

14. Automated Visible Inspection

One of the promising purposes of AI in high quality management is automated visible inspection. Through the use of machine imaginative and prescient and deep studying algorithms, producers can automate the method of figuring out defects and anomalies in merchandise. This not solely saves time and reduces the chance of human error but additionally permits for extra constant and correct product inspection.

A number one electronics producer applied an AI-powered visible inspection system and noticed a 90% discount in false positives and a 50% enhance in defect detection accuracy. By leveraging AI, they improved product high quality and lowered the prices related to handbook inspections

15. Defect Detection and Classification

AI may also be used to detect and classify defects in merchandise robotically. By coaching machine studying fashions on huge datasets of faulty and non-defective merchandise, producers can create programs that may shortly and precisely determine points and categorize them primarily based on severity and sort.

A worldwide automotive provider used AI to detect and classify defects of their injection-molded components, leading to a 75% discount in scrap charges and a 50% enhance in manufacturing effectivity. By leveraging the ability of AI, they improved product high quality and lowered waste, finally saving money and time.

16. Predictive High quality Analytics

AI may also be used to foretell potential high quality points earlier than they happen. By analyzing knowledge from numerous phases of the manufacturing course of and utilizing machine studying algorithms to determine patterns and anomalies, producers can proactively tackle potential points and stop defects from occurring within the first place.

A number one pharmaceutical producer used predictive high quality analytics to cut back batch failure charges by 30%. By figuring out potential points early within the manufacturing course of and taking corrective actions, they improved product high quality and lowered the prices related to scrap and rework.

Implementing AI Options in Manufacturing

Implementing AI options in manufacturing may be advanced and difficult, however the advantages are effectively well worth the effort. Consequently, it’s important to method the implementation course of strategically and systematically.

Figuring out the Proper Use Instances

Step one in implementing AI in manufacturing is figuring out the best use circumstances. It includes:

Fastidiously analyze your manufacturing processes.

Figuring out areas the place AI use circumstances in manufacturing can have essentially the most vital affect.

Prioritizing these use circumstances primarily based on their potential return on funding.

For instance, a number one industrial gear producer recognized predictive upkeep as a high-priority use case for AI. By implementing an AI-powered predictive upkeep system, they have been capable of scale back unplanned downtime by 25% and enhance general gear effectiveness by 15%.

Knowledge Assortment and Preparation

When you’ve recognized the correct use circumstances, the subsequent step is to gather and put together the info wanted to coach and validate your AI fashions. In flip, this includes figuring out the related knowledge sources, cleansing and preprocessing the info, and making certain that it’s in a format that your AI algorithms can simply eat.

Selecting the Proper AI Instruments and Platforms

Lastly, it’s important to decide on the best AI instruments and platforms to help your implementation efforts. This includes evaluating numerous choices primarily based on components corresponding to scalability, ease of use, and compatibility along with your present programs and processes.

A number one aerospace producer selected a cloud-based AI platform to help their digital twin initiatives. By leveraging the scalability and suppleness of the cloud, they have been capable of shortly and simply create digital twins of their merchandise and processes, enabling them to optimize designs, simulate efficiency, and speed up innovation.

Implementing AI use circumstances in manufacturing is a journey, however the advantages may be genuinely transformative with the best method and instruments. By leveraging the ability of AI to optimize processes, enhance high quality, and drive innovation, producers can keep forward of the curve and thrive in an more and more aggressive panorama.

Key Takeaway:

Predictive analytics in manufacturing saves money and time by anticipating points earlier than they happen. This proactive method ensures smoother, extra environment friendly manufacturing.

Tools Failure Prediction: AI analyzes sensor knowledge to foretell breakdowns, decreasing downtime and boosting productiveness.

Manufacturing High quality Optimization: AI helps determine high quality points early, resulting in vital enhancements in product high quality.

Course of Parameter Optimization: Fantastic-tune processes utilizing historic knowledge for max effectivity and price financial savings.

How Markovate Can Assist with Implementing AI in Manufacturing Companies

Markovate focuses on implementing tailor-made AI options for the manufacturing trade, driving effectivity, productiveness, and innovation. Our experience consists of constructing and implementing predictive upkeep programs that use AI to forecast gear failures, decreasing unplanned downtime by as much as 20%. We develop generative design options to create progressive and environment friendly product designs. Moreover, we optimize manufacturing processes to enhance yield charges and lower manufacturing prices.

Our AI-powered robotics and automation embody automated materials dealing with, machine imaginative and prescient for high quality inspection, and collaborative robots (cobots) that improve manufacturing effectivity and employee security. We additionally construct AI instruments for demand forecasting and planning, making certain correct demand predictions for higher manufacturing and stock administration. Moreover, we implement stock optimization programs that scale back stockouts and overstocking by 20-30%.

Moreover, we develop provider threat evaluation instruments to assist mitigate potential disruptions by analyzing monetary stories, information, and social media. We guarantee seamless AI integration with present programs and scalable structure, backed by sturdy knowledge administration. Our complete coaching, steady help, and upkeep maximize the advantages of those AI use circumstances in manufacturing.

FAQs about AI Use Instances in Manufacturing

How will AI integration affect my present manufacturing processes?

AI integration along with your present programs is seamless, making certain minimal disruption to your operations. The options we engineer are designed to reinforce your present processes, offering instant advantages corresponding to lowered downtime, improved effectivity, and higher high quality management. As well as, we optimize stock administration to additional increase general efficiency.

What sort of ROI can I count on from implementing AI options?

Implementing AI options with Markovate can result in vital ROI, together with a discount in unplanned downtime and a rise in yield charges. Furthermore, we obtain a discount in manufacturing prices and an enchancment in stock administration. These enhancements translate to substantial value financial savings and elevated productiveness.

How lengthy does it take to implement an AI resolution?

The implementation timeline for AI options varies primarily based on the complexity of the venture and particular enterprise necessities. Usually, our tasks can vary from just a few weeks for easier options to a number of months for extra advanced integrations. Through the AI session part, we offer an in depth roadmap to make sure clear timelines and milestones.

How does Markovate guarantee knowledge safety and compliance with AI options?

Knowledge safety and compliance are high priorities at Markovate. To guard your knowledge, we implement sturdy knowledge administration practices and cling to trade requirements and rules. Furthermore, our options are designed to make sure knowledge privateness and safety all through the AI lifecycle.

Can Markovate customise AI options to suit the distinctive wants of my manufacturing enterprise?

Completely. We specialise in creating personalized AI options that tackle the particular challenges and necessities of your manufacturing enterprise. Our crew works carefully with you to develop and implement AI programs that align along with your objectives and ship most worth.

How do I get began with Markovate for AI implementation?

Getting began with Markovate is straightforward. Contact us for an preliminary session, throughout which we’ll focus on your enterprise wants, assess your present processes, and description a strategic roadmap for AI implementation. We are going to information you thru each step, from preliminary planning to full-scale deployment and past.

Conclusion

The way forward for manufacturing is right here, and AI use circumstances in manufacturing energy it. From predictive upkeep to generative design, these ten use circumstances showcase AI’s unbelievable potential to revolutionize the way in which we make issues.

However that is only the start. As AI evolves, we’ll see extra progressive purposes emerge, boosting effectivity, high quality, and customization.

The important thing to success will probably be embracing these applied sciences and integrating them into our manufacturing processes. By doing so, we are able to unlock new alternatives for development, competitiveness, and buyer satisfaction.

So, let’s preserve exploring, experimenting, and pushing the boundaries of what’s attainable with AI in manufacturing. The long run is shiny – and it’s ready for us to form it.

[ad_2]