[ad_1]

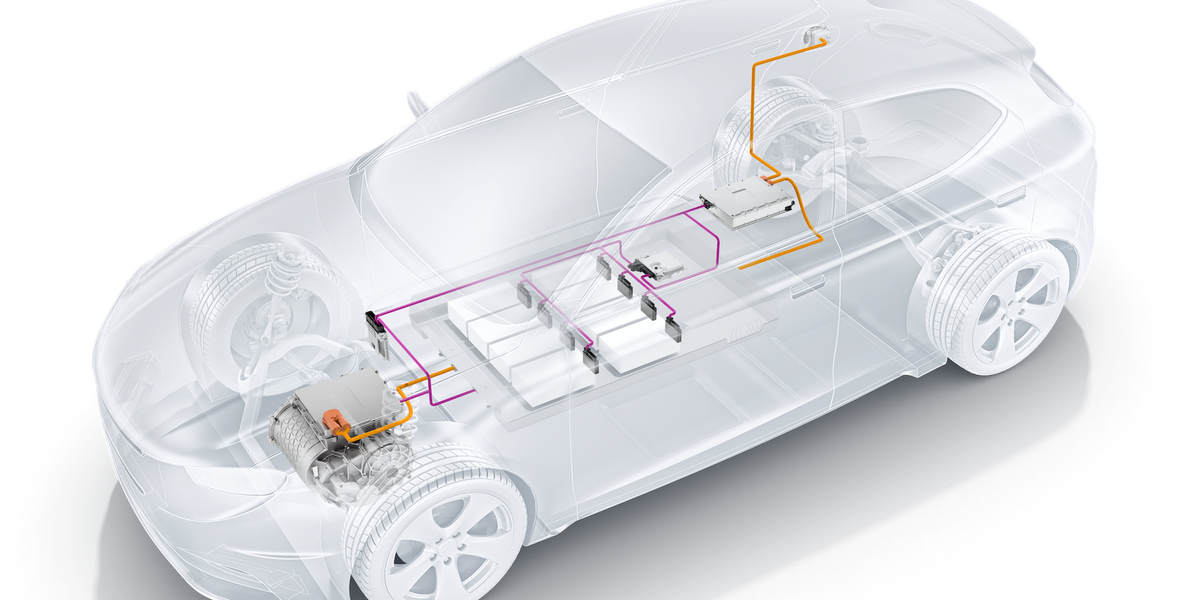

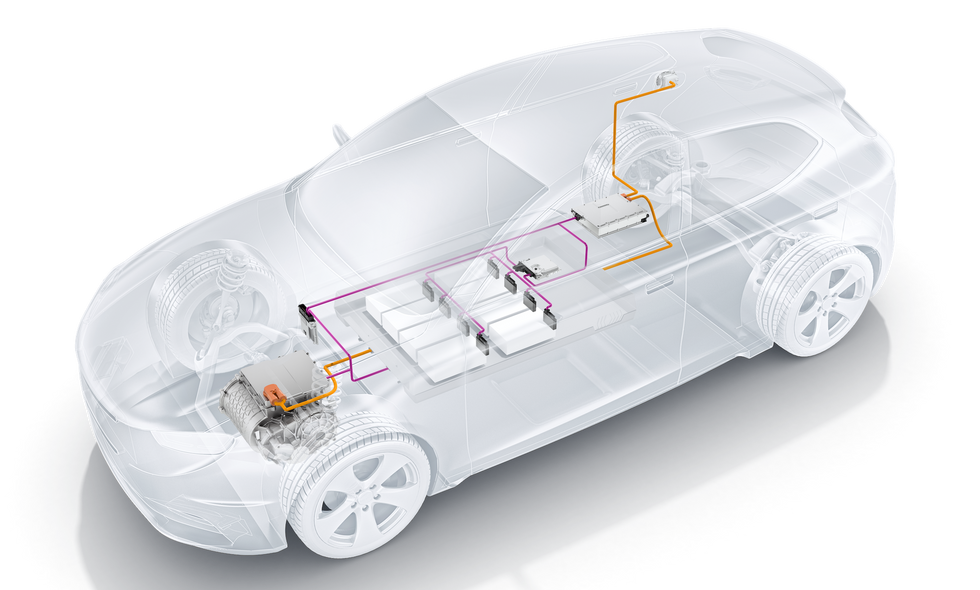

This sponsored article is delivered to you by COMSOL.Simply as vacationers in Paris are drawn to the Louvre, guests to Stuttgart, Germany, additionally flock to museums displaying the good works of town. Stuttgart might not boast of Degas or Monet, however its distinguished names are maybe much more well-known than Paris’ painters: Mercedes–Benz and Porsche. Every of those iconic automakers maintains a museum within the southwestern German metropolis they name house. Their gleaming galleries characteristic many historic and influential automobiles, nearly all of them powered by petroleum-fueled inside combustion (IC) engines. Wanting forward, Stuttgart will seemingly proceed to be the guts of the German auto trade, however how lengthy will the IC engine stay the guts of the auto?Even probably the most profitable producers should adapt to altering situations. The German automotive sector, together with its world counterparts, is doing so by creating elektrische autos. Electrical automobiles are an essential focus of Robert Bosch — one other main automotive firm based in Stuttgart. At present, Bosch provides electrical powertrains, programs, and elements to automakers worldwide.Because the automotive trade races towards an electrified future, Bosch is accelerating its R&D into the important constructing blocks of electrical drivetrains. One in every of these elements is the inverter, which modifications direct present (DC) from the automotive’s batteries into alternating present (AC) to energy its drive motor (Determine 1). The inverter’s skill to supply a clean movement of present is determined by its integral DC hyperlink capacitor (Determine 2). “The capacitor is likely one of the costliest elements of the inverter. Its efficiency has a direct influence on the efficiency and reliability of the inverter, which is prime to the operation of the drivetrain,” explains Martin Kessler, Bosch senior professional for automotive electronics.For the worldwide automotive sector to satisfy its formidable electrification objectives, inverters and their capacitors should bear steady enchancment and optimization. Martin Kessler and his workforce depend on multiphysics simulation to check and refine Bosch’s DC hyperlink capacitors. Their simulation-enabled predictive evaluation enhances and optimizes the reside prototyping of latest designs. “It’s merely not potential to foretell potential issues with testing alone; we’d like each simulation and prototyping working hand in hand,” says Kessler.The Rising Period of the Electrical Car

“Drivers, begin your engines!” As if heeding the decision to start a worldwide race, individuals in every single place start their days by firing up a rumbling IC engine. However this acquainted sound can appear ominous, particularly because the environmental influence of auto emissions grows extra obvious. To reduce these emissions and their contribution to world local weather change, the auto trade is ramping up the manufacturing of electric-powered automobiles and vans. Lots of the electrical autos obtainable at the moment have acquainted model names, however below the hood, these automobiles usually depend on the know-how and experience of outdoor suppliers.

It’s price noting simply how vital a shift that is for a significant world trade. Main automakers are among the world’s largest employers, and an enormous share of their staff, R&D, and manufacturing capability is devoted to producing IC engines. The centrality of inside combustion to those corporations might be discovered of their names, from Common Motors to Bayerische Motoren Werke (higher generally known as BMW). Why would corporations recognized for his or her engines flip to outsiders to make their automobiles go? Maybe it’s as a result of, in a way, electrification is forcing the trade to discover ways to produce a wholly totally different sort of machine.Anatomy of an Electrical Drivetrain

To make a completely electrical automotive, it isn’t sufficient to exchange the engine with an electrical motor and the fuel tank with a battery. Such acquainted gadgets are solely elements of a bigger system, which helps ship clean, dependable efficiency by adjusting to the always various situations below which each and every car should function (Determine 3).

Indispensable Inverter, Essential Capacitor

The function of the inverter in an automotive drivetrain is easy in idea, however complicated in apply. The inverter should fulfill the AC calls for of the motor with the DC supplied by the battery, however it should additionally modify to ongoing fluctuations in load, cost, temperature, and different elements that may have an effect on the habits of every a part of the system. All of this should happen inside tight value and spatial constraints, and the element should maintain this efficiency for years to return.

To grasp the inverter’s operate, think about what a three-phase AC motor wants to be able to function. If related to DC, the motor merely won’t rotate. As an alternative, it have to be supplied with alternating present with three distinct however complementary waveforms, enabling the motor’s three-part discipline coil to magnetically appeal to the segments of its rotor in a sequential sample. “To regulate the exercise of the motor, we should management the amplitude and frequency of the inverter’s present output,” explains Kessler. “The velocity of the motor is proportional to frequency, whereas amplitude helps decide its torque.”“The specified present waveform by way of the transistors has a comparatively steep gradient. The one approach to obtain switch-mode present with this excessive gradient is to have very low inductance within the supply path,” Kessler says. Inductance is the actual pressure opposing modifications in present movement. Each slight change in present will probably be restricted by an induced counteracting voltage, which can disrupt the specified waveform — and the graceful rotation of the motor.To cut back the inductance within the supply path of the transistors, a capacitor is positioned in parallel throughout the enter lead from the battery, which is known as the DC hyperlink. The DC hyperlink capacitor (Determine 5) is positioned in direct proximity to the transistors and offers the specified present waveforms by way of the transistors. The low impedance of the capacitor minimizes any remaining ripple voltage on the battery aspect.A typical capacitor consists of two electrodes separated by an insulating hole, which can merely be airspace or some type of materials. On this utility, Bosch makes use of capacitors made with metallized polypropylene movie. A skinny coating of steel (forming the electrodes) is sprayed on both sides of the movie, which offers the mandatory dielectric hole. The metallized movie is then wound tightly right into a canister form. As with the inverter itself, the capacitor’s conceptual simplicity conceals a multifaceted engineering design downside.Challenges with DC Hyperlink Capacitor Design for Automobile InvertersCapacitors are broadly obtainable elements which can be put in in numerous digital gadgets. For the previous seven years, Martin Kessler has been liable for DC hyperlink capacitor design at Bosch. He has been with the corporate since 1989 and has labored on electrical automotive know-how since 2010. That such an skilled engineer is devoted to this one element reveals its significance — and its complexity.“Why can we not simply decide up a capacitor from {the marketplace}?” asks Kessler, rhetorically. “There are a number of interdependent elements at work. First, we now have excessive calls for for efficiency and reliability. Second, there are very tight spatial necessities. Third, we face tough thermal constraints, because the polypropylene movie in a capacitor can solely stand up to temperatures as much as round 105°C. This problem is compounded by the interplay of electromagnetic and thermal exercise all through the inverter. And at last, the capacitor is comparatively costly,” Kessler explains.Simulation (Not Luck) Helps Remedy the Black Field ProblemTo meet the design challenges of a DC hyperlink capacitor, Kessler developed a course of that mixes experimental testing with multiphysics simulation. For example of why simulation-based evaluation is a obligatory a part of his work, he cites the issue of discovering and measuring potential sizzling spots, the place excessive warmth and paired results may cause failures. “We attempt to find sizzling spots by putting lots of thermocouples inside prototypes and measuring temperatures at varied load factors,” Kessler says. “However my mantra is that you’ll by no means discover a sizzling spot like this with out lots of luck! You will have to be fortunate to position the thermocouple in the best place,” he laughs.“A easy 2D mannequin of a capacitor can be inadequate,” Kessler continues. “The inverter is a distributed system with inside resonances and a fancy loss distribution. Our coupled EM and thermal evaluation should account for pores and skin results and proximity results. We can not calculate an absolute worth for peak temperatures and not using a 3D finite component method, which additionally permits us to mannequin the spatial distribution of coupled EM and thermal results. This is a perfect process for the COMSOL Multiphysics software program,” Kessler says. (Figures 6–7)Kessler’s design course of validates simulation fashions towards measured outcomes, the place potential, after which makes use of the validated fashions to pinpoint potential issues (Determine 8). “By serving to us find sizzling spots within the mannequin, the simulation helps us keep away from points that may have appeared late within the growth course of, and even after manufacturing had began,” says Kessler. “As an alternative, we are able to get particular outcomes and make changes early within the course of.”“We carry out EM modeling and validation of each new design. We evaluate the calculated equal sequence resistance (ESR) curve with the ESR curve as measured from a prototype (Determine 9). If these curves are aligned, we are able to arrange boundary situations for stationary and transient warmth calculations,” says Kessler. “We are able to evaluate the temperature curves from our thermocouples with the outcomes of probes within the COMSOL Multiphysics mannequin. In the event that they match, we are able to then simulate all of the crucial factors the place we should maintain temperatures inside limits.” The curve knowledge is put into the COMSOL Multiphysics software program through the LiveLink for MATLAB interfacing product.“Earlier than we are able to do that, we now have to consider which elements must be integrated into the mannequin,” says Kessler. “A number of the variables we obtain from the OEM, resembling most DC hyperlink voltage, should not very related to our simulation,” he continues. “However the present, switching frequency, e-machine values, and modulation schemes all assist outline a present spectrum. We have to calculate the present spectrum for all three phases of our output to be able to set up energy losses. As soon as we now have this, we are able to do the harmonic evaluation with COMSOL Multiphysics for the frequencies of the present spectrum. Then we sum up our losses for each harmonic,” Kessler explains.Different essential values embrace the boundary situations, which assist Kessler and his workforce decide coupled results. “We calculate parasitic inductance of the capacitor with the AC/DC Module,” Kessler says. “We additionally discover the whole AC loss distribution by way of the capacitor windings or inside busbar. Then we are able to couple the outcomes and decide a temperature-dependent resistivity of the duvet elements with the Warmth Switch Module,” he says. “This allows us to ascertain the utmost component sizzling spot temperature ensuing from the EM exercise.”Findings from their analyses can then result in design modifications. Kessler explains that every new capacitor design sometimes undergoes three rounds of testing. “With simulation, the advance curve gradient is far steeper from one part to the following. Our data grows shortly, and that is mirrored within the closing product.” The newest technology of Bosch inverters guarantees 6 p.c larger vary and a 200 p.c leap in energy density in comparison with earlier designs.Electrification Shifts into Excessive GearAs automakers convert extra of their product traces to electrical propulsion, Martin Kessler believes that the necessity for speedy, cost-conscious R&D may also enhance. “Electrical mobility is rising up now,” he says. “We anticipate that the OEMs will come to us with extra various wants, for inverters in several energy lessons and that meet tighter spatial constraints,” says Kessler. “I do assume that the variety of merchandise that require new capacitor designs will maintain increasing. With our simulation-driven growth strategies, we’re assured that we are able to sustain with this development.”Within the years to return, maybe guests to Stuttgart’s automotive museums will cease to admire the historic motors and inverters that powered the trade into a brand new electrical age.MATLAB is a registered trademark of The MathWorks, Inc.

[ad_2]