[ad_1]

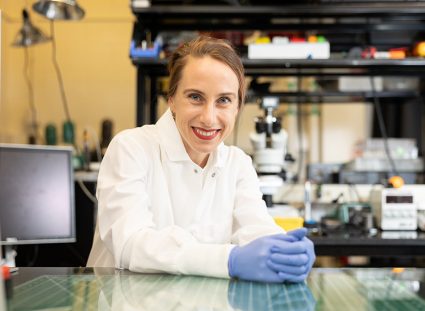

MIT professor of supplies science and engineering and mind and cognitive sciences Polina Anikeeva in her lab. Picture: Steph Stevens

By Jennifer Michalowski | McGovern Institute for Mind Analysis

MIT scientists have developed tiny, soft-bodied robots that may be managed with a weak magnet. The robots, shaped from rubbery magnetic spirals, will be programmed to stroll, crawl, swim — all in response to a easy, easy-to-apply magnetic subject.

“That is the primary time this has been completed, to have the ability to management three-dimensional locomotion of robots with a one-dimensional magnetic subject,” says Professor Polina Anikeeva, whose staff printed an open-access paper on the magnetic robots within the journal Superior Supplies. “And since they’re predominantly composed of polymer and polymers are smooth, you don’t want a really massive magnetic subject to activate them. It’s really a very tiny magnetic subject that drives these robots,” provides Anikeeva, who’s a professor of supplies science and engineering and mind and cognitive sciences at MIT, a McGovern Institute for Mind Analysis affiliate investigator, in addition to the affiliate director of MIT’s Analysis Laboratory of Electronics and director of MIT’s Ok. Lisa Yang Mind-Physique Heart.

The brand new robots are nicely suited to move cargo by means of confined areas and their rubber our bodies are mild on fragile environments, opening the likelihood that the expertise may very well be developed for biomedical purposes. Anikeeva and her staff have made their robots millimeters lengthy, however she says the identical strategy may very well be used to provide a lot smaller robots.

Magnetically actuated fiber-based smooth robots

Engineering magnetic robots

Anikeeva says that till now, magnetic robots have moved in response to transferring magnetic fields. She explains that for these fashions, “if you would like your robotic to stroll, your magnet walks with it. If you’d like it to rotate, you rotate your magnet.” That limits the settings by which such robots could be deployed. “In case you are making an attempt to function in a very constrained surroundings, a transferring magnet might not be the most secure answer. You need to have the ability to have a stationary instrument that simply applies magnetic subject to the entire pattern,” she explains.

Youngbin Lee PhD ’22, a former graduate pupil in Anikeeva’s lab, engineered an answer to this drawback. The robots he developed in Anikeeva’s lab usually are not uniformly magnetized. As an alternative, they’re strategically magnetized in numerous zones and instructions so a single magnetic subject can allow a movement-driving profile of magnetic forces.

Earlier than they’re magnetized, nonetheless, the versatile, light-weight our bodies of the robots should be fabricated. Lee begins this course of with two sorts of rubber, every with a special stiffness. These are sandwiched collectively, then heated and stretched into an extended, skinny fiber. Due to the 2 supplies’ totally different properties, one of many rubbers retains its elasticity by means of this stretching course of, however the different deforms and can’t return to its unique dimension. So when the pressure is launched, one layer of the fiber contracts, tugging on the opposite aspect and pulling the entire thing into a good coil. Anikeeva says the helical fiber is modeled after the twisty tendrils of a cucumber plant, which spiral when one layer of cells loses water and contracts quicker than a second layer.

A 3rd materials — one whose particles have the potential to grow to be magnetic — is included in a channel that runs by means of the rubbery fiber. So as soon as the spiral has been made, a magnetization sample that allows a specific sort of motion will be launched.

“Youngbin thought very rigorously about the right way to magnetize our robots to make them capable of transfer simply as he programmed them to maneuver,” Anikeeva says. “He made calculations to find out the right way to set up such a profile of forces on it once we apply a magnetic subject that it’ll really begin strolling or crawling.”

To type a caterpillar-like crawling robotic, for instance, the helical fiber is formed into mild undulations, after which the physique, head, and tail are magnetized so {that a} magnetic subject utilized perpendicular to the robotic’s airplane of movement will trigger the physique to compress. When the sphere is lowered to zero, the compression is launched, and the crawling robotic stretches. Collectively, these actions propel the robotic ahead. One other robotic by which two foot-like helical fibers are linked with a joint is magnetized in a sample that allows a motion extra like strolling.

Biomedical potential

This exact magnetization course of generates a program for every robotic and ensures that that when the robots are made, they’re easy to regulate. A weak magnetic subject prompts every robotic’s program and drives its specific sort of motion. A single magnetic subject may even ship a number of robots transferring in reverse instructions, if they’ve been programmed to take action. The staff discovered that one minor manipulation of the magnetic subject has a helpful impact: With the flip of a swap to reverse the sphere, a cargo-carrying robotic will be made to softly shake and launch its payload.

Anikeeva says she will be able to think about these soft-bodied robots — whose easy manufacturing will probably be simple to scale up — delivering supplies by means of slender pipes, and even contained in the human physique. For instance, they could carry a drug by means of slender blood vessels, releasing it precisely the place it’s wanted. She says the magnetically-actuated gadgets have biomedical potential past robots as nicely, and would possibly sooner or later be included into synthetic muscle mass or supplies that help tissue regeneration.

PAPER – Magnetically Actuated Fiber-Based mostly Smooth Robots. Youngbin Lee, Florian Koehler, Tom Dillon, Gabriel Loke, Yoonho Kim, Juliette Marion, Marc-Joseph Antonini, Indie Garwood, Atharva Sahasrabudhe, Keisuke Nagao, Xuanhe Zhao, Yoel Fink, Ellen T. Roche, and Polina Anikeeva. Superior Supplies, 2301916.

MIT Information

[ad_2]