[ad_1]

by Nicolas Lauzier.

Final up to date on Jul 17, 2024 10:49 AM

Posted on Jul 17, 2024 10:33 AM. 4 min learn time

As we navigate by way of 2024, forward-thinking producers are setting their sights on the horizon, anticipating the financial upswing projected for 2025. On this context, investing in automation emerges as a strategic choice that may place firms for achievement when market situations enhance.

Automation: the aggressive edge in manufacturing

Deloitte’s 2024 manufacturing {industry} outlook [1] additional helps this view, highlighting the important want for producers to embrace digital transformation and sensible manufacturing facility options to remain aggressive. The report reveals that an amazing 86% of surveyed manufacturing executives imagine sensible manufacturing facility options would be the major drivers of competitiveness within the subsequent 5 years [1].

Economist Alan Beaulieu, president of ITR Economics, strongly advocates for this proactive strategy. He emphasizes the significance of getting ready for future development by investing in automation and robotics now, warning that “firms that don’t put money into automation now will discover themselves taking part in catch-up when financial situations enhance in 2025” [2]. This knowledgeable perception reinforces the urgency of adopting automated options like palletizing programs within the present financial local weather.

Labor scarcity is anticipated to worsen

Research present that along with anticipating an financial restoration, the labor scarcity producers presently face shouldn’t be prone to diminish; actually, it’s anticipated to worsen. In keeping with Deloitte [3], even when each expert employee in America was employed, there would nonetheless be 35% extra unfilled job openings within the sturdy items manufacturing sector than expert staff able to filling them. It predicts a scarcity of greater than two million American manufacturing staff by 2030.

The labor scarcity is anticipated to worsen. Presently, round 40 million Child Boomers stay within the workforce, making up 25% of the full workforce, with many occupying conventional manufacturing roles. As these Boomers retire, youthful staff are more and more choosing jobs with higher working situations and compensation, steering clear of producing positions.

Cobots convey automation inside attain

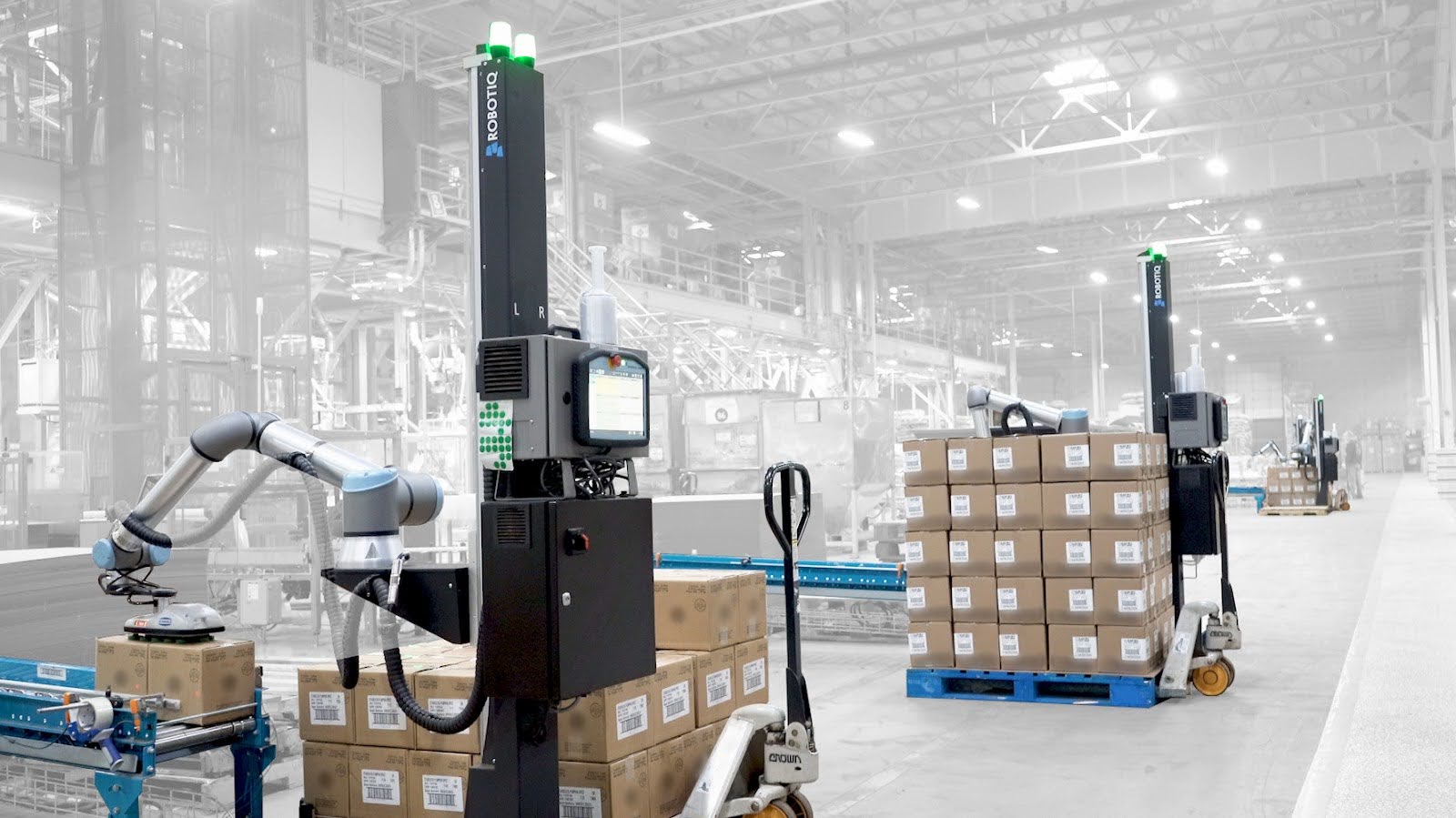

Latest improvements in automation have made this transition extra accessible than ever earlier than. Collaborative robotic (cobot) palletizers, particularly, have seen vital developments, turning into extra performant, versatile, and simpler to combine than their predecessors. These developments have democratized automation, making it now not the unique area of enormous producers. Small and medium-sized enterprises can now leverage these applied sciences to compete successfully within the international market.

A main instance of this new wave of accessible automation are the Robotiq Lean Cobot palletizers, options designed with ease of use and suppleness in thoughts. These programs embody the ideas of lean manufacturing, providing a cheap (a ROI of lower than a yr), space-efficient, and quickly deployable resolution for companies of all sizes. The Robotiq cobot palletizers exhibit how fashionable automation may be tailor-made to the precise wants of every producer, no matter their scale of operations.

By embracing these revolutionary options, producers can’t solely put together for the financial upturn but in addition domesticate a tradition of steady enchancment and flexibility. As we glance in direction of 2025 and past, those that put money into sensible, versatile automation options like cobot palletizers might be well-positioned to thrive within the evolving manufacturing panorama, turning the challenges of immediately into the aggressive benefits of tomorrow.

References

[1] Deloitte. “2024 Manufacturing Business Outlook.” https://www2.deloitte.com/us/en/insights/{industry}/manufacturing/manufacturing-industry-outlook.html

[2] Management Engineering. “Manufacturing, international economic system 2024-2025: Quick-term ache, then development.” https://www.controleng.com/articles/manufacturing-global-economy-2024-2025-short-term-pain-then-growth/

[3] Creating pathways for tomorrow’s workforce todayhttps://www2.deloitte.com/us/en/insights/{industry}/manufacturing/manufacturing-industry-diversity.html/#the-future

[ad_2]