When most individuals consider putting in a robotic cell, they think about a course of that takes half a 12 months, perhaps extra. Countless design opinions, integration delays, and operator coaching that drags on for weeks.

But it surely doesn’t should be that means.

With the Lean Robotics methodology, we’ve seen producers go from “we must always automate” to a totally working robotic cell in as little as 90 days. Right here’s how.

Why velocity issues

Time is cash. The sooner you deploy automation, the earlier you:

Cut back labor bottlenecks

Enhance throughput

Seize ROI

Lengthy timelines kill momentum. They drain enthusiasm out of your staff, delay your return, and in some circumstances, stall the undertaking solely.

That’s why a structured, time-bound strategy is vital.

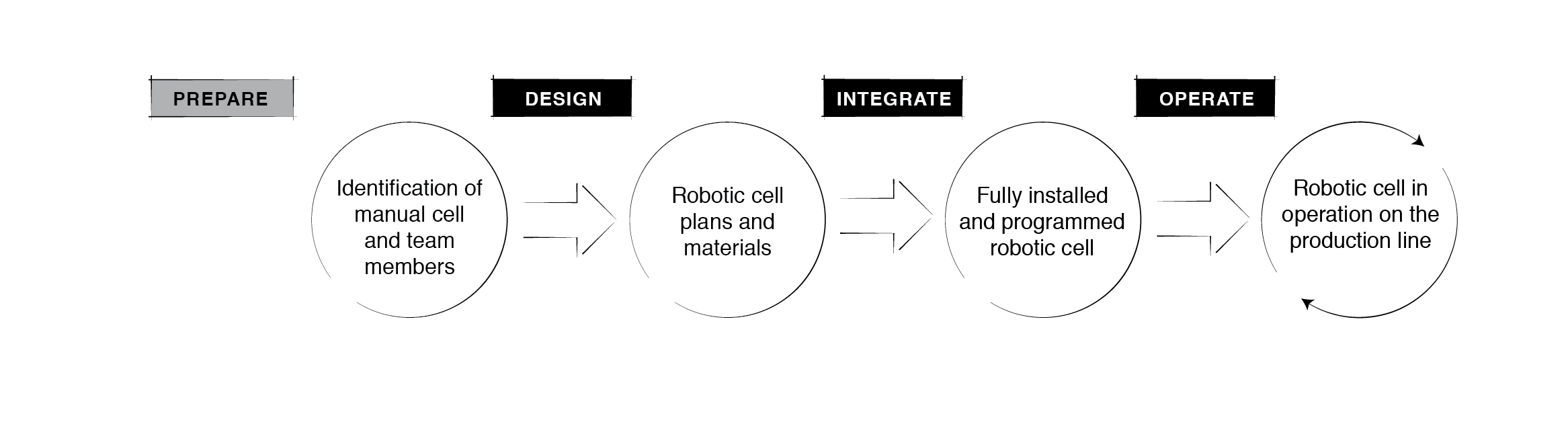

The Lean Robotics 90-day roadmap

Month 1 – Design

As a substitute of beginning with the robotic, begin together with your cell’s output.

Outline the “buyer” to your cell (usually the following step within the course of).

Decide the amount, high quality, and tempo that course of wants.

Design your structure for circulation, security, and ease of use.

Professional tip: Keep away from overengineering. Focus solely on the options you want for this part of manufacturing. You may at all times broaden later.

Month 2 – Combine

That is the place you flip the plan into actuality:

Assemble your cell with standardized, pre-tested parts the place attainable.

Program offline to save lots of on manufacturing downtime.

Check with practical manufacturing inputs—don’t wait till set up to find points.

Professional tip: Preserve integration lean. Overcomplication at this stage results in delays and future complications.

Month 3 – Begin to function

As soon as the cell is put in, it’s time to:

Practice operators for confidence and luxury, not simply compliance.

Run at low quantity first, gathering suggestions out of your staff.

Optimize primarily based on real-world efficiency earlier than scaling to full output.

Professional tip: Doc the whole lot—layouts, applications, SOPs—so your subsequent cell goes in even sooner.

What you acquire by transferring quick

Faster ROI – You begin saving sooner.

Crew buy-in – A brief, profitable deployment builds confidence for future automation.

Standardization – Classes out of your first 90-day undertaking develop into the blueprint for the following.

Lean Robotics makes it attainable

The 90-day timeline is about eradicating the waste that slows tasks down. With the best framework, instruments, and mindset, your staff can go from clean ground area to a productive robotic cell in simply three months.

Need to see how this might work in your manufacturing facility?

👉 Take a deep dive into these ideas together with your FREE digital model of the Lean Robotics e-book (or order a bodily copy!)

👉 See if a Robotiq Palletizing Resolution is an efficient match to your manufacturing facility. Merely reply a sequence of questions and we’ll ship you a personalized 3D simulation and report exhibiting precisely which answer matches your manufacturing facility area and wishes in only a matter of minutes!