[ad_1]

The Apollo 13 moon mission didn’t go as deliberate. After an explosion blew off a part of the spacecraft, the astronauts spent a harrowing few days attempting to get dwelling. At one level, to maintain the air breathable, the crew needed to cobble collectively a converter for ill-fitting CO2 scrubbers with duct tape, house swimsuit components, and pages from a mission handbook.

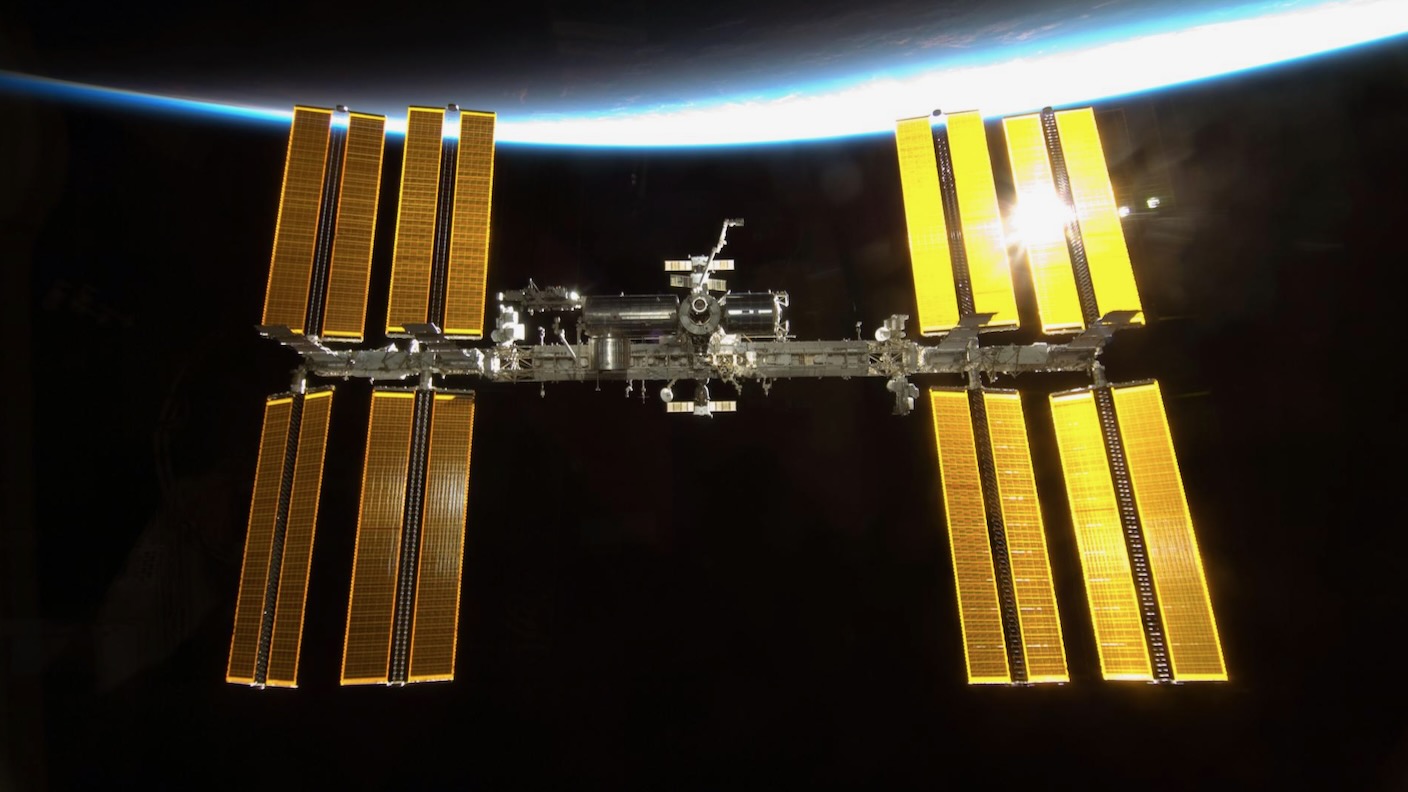

They didn’t make it to the moon, however Apollo 13 was a grasp class in hacking. It was additionally a grim reminder of simply how alone astronauts are from the second their spacecraft lifts off. There are not any {hardware} shops in house (but). So what fancy new instruments will the following era of house hackers use? The primary 3D printer to make plastic components arrived on the ISS a decade in the past. This week, astronauts will take supply of the primary metallic 3D printer. The machine ought to arrive on the ISS Thursday as a part of the Cygnus NG-20 resupply mission.

The primary 3D printer to print metallic in house, pictured right here, is headed to the ISS. Picture Credit score: ESA

Constructed by an Airbus-led group, the printer is in regards to the measurement of a washer—small for metallic 3D printers however huge for house exploration—and makes use of high-powered lasers to liquefy metallic alloys at temperatures of over 1,200 levels Celsius (2,192 levels Fahrenheit). Molten metallic is deposited in layers to steadily construct small (however hopefully helpful) objects, like spare components or instruments.

Astronauts will set up the 3D printer within the Columbus Laboratory on the ISS, the place the group will conduct 4 check prints. They then plan to convey these objects dwelling and examine their power and integrity to prints accomplished below Earth gravity. Additionally they hope the experiment demonstrates the method—which includes a lot larger temperatures than prior 3D printers and dangerous fumes—is secure.

“The metallic 3D printer will convey new on-orbit manufacturing capabilities, together with the likelihood to supply load-bearing structural components which might be extra resilient than a plastic equal,” Gwenaëlle Aridon, a lead engineer at Airbus stated in a press launch. “Astronauts will be capable of immediately manufacture instruments akin to wrenches or mounting interfaces that might join a number of components collectively. The pliability and fast availability of 3D printing will vastly enhance astronauts’ autonomy.”

One in every of 4 check prints deliberate for the ISS mission. Picture Credit score: Airbus House and Defence SAS

Taking almost two days per print job, the machine is hardly a velocity demon, and the printed objects will likely be tough across the edges. Following the primary demonstration of partial-gravity 3D printing on the ISS, the event of applied sciences appropriate for orbital manufacturing has been gradual. However because the ISS nears the top of its life and personal house station and different infrastructure tasks ramp up, the expertise may discover extra makes use of.

The necessity to manufacture gadgets on-demand will solely develop the additional we journey from dwelling and the longer we keep there. The ISS is comparatively close by—a mere 200 miles overhead—however astronauts exploring and constructing a extra everlasting presence on the moon or Mars might want to restore and substitute something that breaks on their mission.

Ambitiously, and even additional out, metallic 3D printing may contribute to ESA’s imaginative and prescient of a “round house financial system,” wherein materials from previous satellites, spent rocket phases, and different infrastructure is recycled into new buildings, instruments, and components as wanted.

Duct tape will little doubt at all times have a spot in each house hacker’s field of instruments—however a couple of 3D printers to whip up plastic and metallic components on the fly actually gained’t harm the trigger.

Picture Credit score: NASA

[ad_2]